Product Search>>

search

|

I. The Functions of Lubricants: 1.Sealing: They can form a dynamic seal between screws and compression chambers, and between male and female screws, to reduce leakage of refrigerants from the high pressure side to the low pressure side in the compression process. 2.Cooling: They serve to cool down the compressed refrigerants. The lubricants are injected into the compressor to absorb the heat generated by the refrigerant gas in the compression process, and reduce the temperature of the exhaust gas. 3.Lubricating: They can form an oil film between the bearing and screws to support the rotor and play the function of lubricating. 4.Adjusting: They can transfer the force of pressure differences, drive the capacity regulating system and adjust the position of the capacity slider through the actions of loading and unloading the solenoid valve of the compressor, to realize the adjustment of compressor capacities. 5.Reducing operating noise. II. The lubricants inside compressors are the key to maintain the normal operation of compressors. The general problems of lubricants include: 1.Deterioration of lubricants due to high temperature effects, resulting in the loss of lubrication. 2.Contamination lubricants caused by the entering of foreign matters which blocks the filter. 3.Erosion of the motor due to water pollution and acidification of the system.

III. Instructions for Using Lubricants

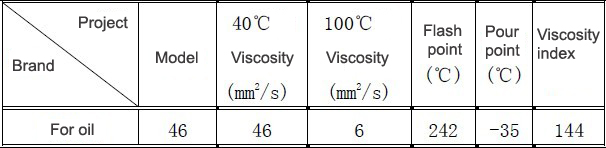

Usually, it is required to check or change the lubricant once every 10,000 hours of operation, and after the first operation, it is recommended to change the lubricant and clean the oil filter once every 2500 hours of operation. Because the residues left after system assembly will be accumulated in the compressor after operation, it is necessary to change the oil once every 2500 hours (or 3 months); afterwards, the oil can be changed depending on the cleanliness of the system. If the system is fairly clean, change the oil every 10,000 hours (or a year). If the discharge temperature of the compressor remains at the high-temperature state for a long time, the deterioration progress of the lubricant will get faster; it is necessary to check the chemical properties of the lubricant on a regular basis (every two months), and change it when it does not comply with the standard. If it is not possible to conduct regular check, refer to the recommended values in the following table for operations.

Note: The operation period is calculated by 16 hours/day IV. Replace frozen lubricant and make internal cleanup: The action for releasing the oil is as mentioned earlier. After the refrigeration oil is excluded clean and the internal and external pressures of the compressor have reached a balance, use a hex wrench to loose the flange bolts. After the connector of the oil filter and the flange in the cleaning hole (or the flange on the oil level switch) are removed, remove the contaminants in the sump of the compressor and check whether the meshed screen of the oil filter has any damages, and then blow off the sludge and pollutants on it, or replace it with a new oil filter. Please be noted that when replacing it with a new filter, screw tight the nuts on the port of the filter and seal it well to prevent internal leakage; the inside gasket of the oil filter connector must be replaced with a new one to prevent internal leakage; it is also recommended to change other flange gaskets. Cautions: 1. Do not mix frozen lubricants of different branches, especially mineral oils and synthetic ester oils, which should never be mixed. 2. When replacing the frozen lubricant with a different branch, make sure to discharge the remnants of the original frozen lubricant in the system. 3. Because some oil branches have the hydroscopic property, do not expose freeze oil to the air for a long time. During the installation, try to shorten the time of exposure as much as possible, and conduct vacuuming properly. 4. If such an accident as burnt compressor motor has occurred before, pay special attention to removing the acidic remnants in the system when replacing the old motor with a new one, and check the acidity of the refrigeration oil 72 hours after the debugging operation. It is recommended to replace the refrigeration oil, dry the filter, and reduce the potential etching. After that, run the system for about a month before re-test it or replace the refrigeration oil once again. 5. If such an accident as water seepage has occurred to the system, pay special attention to removing the water completely; in addition to replacing the refrigeration oil, it is necessary to pay special attention to checking the acidity of the oil, replace it with new oil and dry the filter promptly. |

Webpage Copyright©2012 Shanghai Globe Screw Technology Co., Ltd. Powered by www.300.cn|No.:沪ICP备05025085号